The Scubapro 450 is based on Seikos 6306-7001 model, and were produced in the late 1970’s as part of a marketing contract in conjunction with the Scuba-pro dive equipment company. The model it’s based on is a Japanese domestic market watch produced alongside the very similar 6309-7040. The difference between the calibre 6306 and 6309 is the 6306 has a kanji day wheel, has four extra jewels, it has a hacking mechanism and has different machining around the crown making the opening slightly larger. The difference between the Scubapro 450 and a stock 6306 is just the printing on the dial. The most obvious difference is the “Scubapro 450” script situated above the “Water 150 Resist” on the dial, but a harder to see change is the dial code went from 700L T to 700J T. It’s generally accepted that the Scubapro versions were produced between 1978 and 1979 but to muddy the waters examples have surfaced with caseback dates of 1976, 77, and 83. Were these actually produced in those years or have the casebacks been changed? The 1983 example is doubly strange because that one post dates 6306’s end of production date of 1981! As ever with vintage Seiko nothing is clear cut – part of the appeal maybe? The example featured below is in outstanding condition and belongs to a very knowledgeable UK collector. It came in for a full movement service so I seized the chance to document it!

As can be seen the caseback shows a production date of March 1978, perfect for the verified production dates.

Undo the back and a beautifully clean movement is exposed.

Drop the movement out and the pristine dial and handset can be seen. Genuine Scubapro dials have that very slight pale blue cast to the additional printing, something the fakes haven’t been able to reproduce to date. Note the deep bevel around the date window, indicative of Suwa produced dials pre 1981, after this date the bevel became less pronounced.

With the dial, handset and day wheel removed the calendar side is looking super clean.

The stripdown continues, it’s actually a pleasure working on such an unabused example!

With the keyless work removed you can see the first glimpse of one of the differences between this and a 6309 movement, namely the end of the hacking lever peeping out.

With the movement turned over everything is looking in excellent shape.

And with the autowind mechanism removed you can see the other difference between a 6306 and a 6309, namely the diafix anti shock protection on the escape and 3rd wheel pivots. These add 4 jewels to the 17 count of the 6309, in the picture the springs and caps have already been removed.

The train bridge has been removed in this picture, note the hacking lever situated to the left of the movement.

This was the only muck I found in the whole movement, an isolated occurrence on the third wheel.

The movement in its constituent parts ready for cleaning.

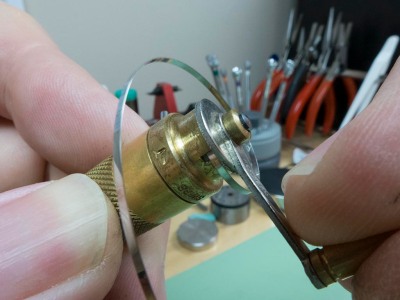

Once cleaned and inspected the rebuild began, the first job as usual was to start with the mainspring. I thought I’d walk you through the mainspring refitting procedure, this is the tool needed to fit a spring into its barrel nice and cleanly. Springs can be hand wound into their barrels but it’s hard on the fingers and you tend to end up with flakes of skin and muck under the spring and it all gets a bit messy. Once you’ve mastered the mainspring winder you’ll wonder why you struggled without one!

Mainspring winders come with various sized ends for different sized springs and barrels. Most 60’s and 70’s Seiko calibres can be refitted with the number 7 end. The spring is pressed onto the arbor where the tab engages in the hole on the end of the spring allowing it to grip and wind it.

The winder is placed into the tools barrel. this has a moveable plate that can be depressed to eject the spring into the barrel when it’s fully wound.

The winder is put in place ensuring the coil enters through the slot in the barrel wall, you then wind until the end disappears into the barrel.

Once fully wound in it looks like this from below, any particles that have stuck to the spring can now be cleaned with a piece of Rodico.

A coating of braking grease is spread around the barrel wall to lubricate and prevent the spring slipping to early during the winding process.

The tools end is then placed into the barrel and the button is pressed on the top of the tool to eject the spring.

The tool can now be removed.

The arbor is then lubricated and placed in the centre of the spring. The tab on the arbor has to be located into the slot in the spring.

The arbor is clipped into place and the spring is lubricated, if you’re fitting a new mainspring they come pre-lubricated and don’t need any more.

The last thing to do is close the barrel up with the cap.

A very fiddly job on any Seiko with diafix shock protection is replacing the actual diafix caps and springs. These little blighters can ping off into the distance if your not careful and you’ll never find them again! My method is to lubricate the cap with the correct oil, remember the escape wheel and third wheel are located in these jewels and both take different oils. Replace the cap on top of the jewel and with the “fallopian tube” type spring standing upright locate each leg under the rim of the housing.

Fold the spring down and clip the tab under the rim so the cap is held in three places. It sounds simple but it took a long time before I became proficient at getting them in cleanly!

Repeat with the next one, remember the correct grade of lubricant!

The motion work’s coming together here.

The bridge has been refitted in this shot.

And the autowind assembly has been rebuilt and fitted here.

The calendar side coming together.

A shot of the kanji day wheel here.

The beautiful dial is refitted here.

A closer shot shows the linen type texture of the lume plots, a sure fire pointer to the fact this is the lume it left the factory with. You can also see the 700J T dial code at the bottom.

The handset refitted….

….and the movement recased.

What an exemplary example of this rare 1970’s diver this particular watch is!

Thoroughly enjoyed this documented review, many thanks for taking the time!

I am fairly new to the world of Seiko turtle pieces (and watches in general), but I am becoming increasingly drawn to a desire to begin collecting such examples. This 1978 model would be a fabulous price to own, being my birth year.

Regards

LikeLike

Second picture: “As can be seen the caseback shows a production date of March 1978, perfect for the verified production dates.” For the life of me I cannot see that – can you explain to the initiated (me), please?

LikeLike

The first two characters of the serial number indicate the production date, 8 is the year (1978) and 3 is month (March). You do need to know the decade in which the watch was produced of course! If the second character is O,N or D that’s Oct, Nov and Dec.

LikeLike

Thank you, that is really illuminating. However, this raises a subsidiary question. In your first paragraph you state that “to muddy the waters examples have surfaced with caseback dates of 1976, 77, and 83.” How would you know that the date was 1983 if you have to know the decade the natural assumption might be to assume it was ’73? Or was the Seiko 6306-7001 model simply not produced that early so a code starting with a ‘3’ could not be ’73 and would therefore have to be ’83?

LikeLike

I recently bought a scubapro and it starts with 81 january 78 plus it carries the “old” dial inscription 700 l t.

I saw it, bought and am still pinching myself because I can’t believe my luck. I buy vintage diver watches as an investment and the new classics of tomorrow. It started back in 1986 when I saw my first seiko diver on someone’s arm and I was swept away. It took me almost 18 years till I finally bought my only ever watch for life. With my luck I bought one of the first SKX007 the 1996. I bought a few more after that eventhough the one I bought first probably will last me a lifetime.

LikeLike

I’m afraid the dial code 700LT must mean it has a fake dial, genuine Scubapros have the dial code 700LJ. The code 700LT is used on the standard Seiko 6306-7001 so it seems like someone has just printed Scubapro on a std 6306-7001 dial.

LikeLike

Still happy with the standard 6306-7001. Good thing I paid not much and it is in mint condition.

Do you think the print will come of without any traces and will it be worth the trouble of getting it removed?

LikeLike

It’s hard to say unless you try but from experience I’d say it’s pretty unlikely it will come off without leaving some damage.

LikeLike

Then we better not just in case it might be the prototype after all. If someone is to forge a well known rare watch I suppose they do a better job or just buy an aftermarket dial.

LikeLike

There are a lot of 6306 700LT dialled ‘Scubapro’ watches out there and I’ve had a few across my bench. These first appeared on the market about 7 or 8 years ago, I think it may have been Loy who printed them but I can’t recall exactly. I think we can safely say it isn’t the prototype!

LikeLike

HI.I HAVE A SCUBAPRO 450,BOTTOM OF DAIL SAYS.6306-700JT,NUMBER ON BACK ID 7D7624. 6309-7290,CAN U TELL ME WHAT YEAR IT IS? IT HAS A STAINLEES STRAP.THANKS

LikeLike

It seems to be very clearly explained above – yours will be December 1977!

“The first two characters of the serial number indicate the production date, 8 is the year (1978) and 3 is month (March). You do need to know the decade in which the watch was produced of course! If the second character is O,N or D that’s Oct, Nov and Dec.”

LikeLike

THATS GREAT THANKS,COULD YOU PUT A VALUE ON IT? ITS V.G.C,THANKS

LikeLike

£457,671 and 59p

LikeLike